For demanding industrial and defense applications, precision, reliability, and durability in laser technology is paramount. Daylight Solutions has applied its expertise in commercializing laser technology to a new generation of Near-Infrared (NIR) diode lasers. These lasers are engineered to excel in the most challenging environments, catering to critical applications such as space communication and LiDAR.

High Reliability and Robust Design

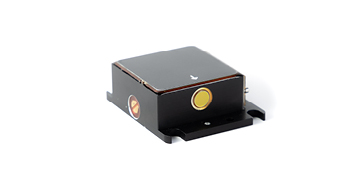

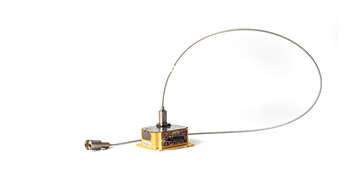

Central to the design philosophy of Daylight Solutions is a commitment to reliability and robustness. Each NIR diode laser we produce is a testament to this commitment, encapsulated in a 6-pin compact butterfly-style package that ensures durability and longevity. The laser modules are hermetically sealed and meticulously designed to be epoxy-free, meeting and exceeding the rigorous standards required for industrial, defense, and space-based applications. This includes earning the coveted EDFA space qualification, underscoring our lasers’ readiness for the harshest conditions imaginable.

Precision Engineering for Optimal Performance

The NIR diodes have integrated thermistors and optional monitor photodiodes to control temperature and power precisely in high-performance applications. These features guarantee optimal performance through accurate temperature monitoring and power control, ensuring your projects achieve unparalleled precision.

Customization for Enhanced Application Suitability

Daylight Solutions recognizes the diverse needs of our clients. To accommodate various application requirements, we offer customizable output fiber options. Choose between the 105 μm 0.15 NA for unparalleled brightness in your applications, or opt for the 0.22 NA fiber for enhanced confinement and optimized coupling efficiency. Our commitment to supporting dense board layouts and streamlining manufacturing processes is evident through our additional services, including pin trimming, bending, and tinning.

Seamless Integration and Manufacturability

Designed with OEM integration in mind, our NIR diode lasers are built for easy incorporation into your existing systems and scalable production. We create these lasers using semi-automated processes. This helps with volume production and integration into various industries. As a result, they become more efficient solutions.

Daylight Solutions’ NIR diode lasers come packed with features designed to elevate your project’s performance. With an output power of 10W and high efficiency that minimizes heat while maximizing power, these lasers are not just powerful but are crafted for endurance. Their hermetic, internally epoxy-free package ensures that they are suitable for the most demanding applications, including space and defense. Manufactured in the USA, these lasers epitomize the fusion of high-quality craftsmanship and cutting-edge technology.

When your laser application calls for outstanding performance with proven reliability, Daylight’s laser components are the right solution.

High-Reliability Diode Pumps in Space Communications

Elevating Space Communication to New Frontiers

Space presents unique challenges and opportunities for communication technologies. As humanity extends its reach, from the establishment of Space Force to the advent of commercial space travel and beyond, the demand for advanced communication methods has never been higher. Traditional radio wave transmission, while effective on Earth, faces limitations in the vastness of space. The susceptibility of radio waves to scattering poses significant security and efficiency challenges, particularly when high-quality, real-time communication is required.

Laser communications, with their shorter wavelengths and narrower beam widths, promise directed, high-speed communication far superior to that of traditional radio waves. This technology, supported by high-reliability NIR diode lasers, is crucial for applications where quick, robust, and high-fidelity communication is paramount.

The Jet Propulsion Laboratory (JPL), a leader in space exploration technology, has been at the forefront of developing and deploying laser communication systems. Their work with the Deep Space Network (DSN) showcases the potential of laser communications to enhance data transmission capabilities significantly, enabling 10 to 100 times more data to be sent back to Earth than is currently possible with radio waves. This advancement is not just about quantity; it’s about the quality and security of the information transmitted, offering a level of encryption that makes it incredibly difficult for unauthorized interception.

Why High Reliability Diode Pumps?

High-reliability diode pumps emerge as the backbone of space communication technologies, specifically infrared laser communication systems, for several reasons:

Precision and Efficiency

The critical mission environments of space demand not only precision but also efficiency. High-reliability diode pumps power laser systems that provide narrower beam widths and shorter wavelengths, enabling focused, high-speed communication channels that are far superior to traditional methods.

Durability in Harsh Conditions

Space is an unforgiving environment, with extreme temperature fluctuations, radiation, and vacuum conditions. High-reliability diode pumps are engineered to withstand these conditions, ensuring consistent performance and longevity of communication systems in space.

Security

In the expanse of space, where distances are vast and the need for secure communication paramount, the ability of high-reliability diode pumps to support laser systems is indispensable. These systems offer a more secure transmission medium, significantly reducing the risk of interception by unauthorized parties. The directed nature of laser beams makes it exceedingly difficult for bad actors to detect or intercept messages, a critical advantage underscored by NASA’s advocacy for laser communications to enable “10 to 100 times more data transmission” than is possible with radio waves.

Data Capacity

The burgeoning field of space exploration and commercial space travel generates colossal amounts of data. High-reliability diode pumps are essential for managing this data deluge, facilitating the transmission of high-quality content, including video and scientific data, with unprecedented speed and efficiency.

The relentless advance of space exploration and the operational demands of entities like Space Force and commercial space ventures necessitate a paradigm shift in communication technologies. High-reliability diode pumps stand at the heart of this transformation, powering laser communication systems that offer the precision, durability, security, and data capacity essential for the next era of space communication. As we push the boundaries of human presence in space, the role of these advanced technologies in overcoming the limitations of traditional radio wave transmission becomes ever more critical, promising a new horizon of possibilities for secure, efficient, and high-speed communication in the vast expanse beyond our planet.

Highlights

Features & Benefits

- 10W output power with demonstrated high reliability

- Hermetic package, internally epoxy-free

- Qualified for space and defense applications

- Highly efficient, minimizing heat and maximizing power

- High brightness in 105 μm/0.15 NA or 0.22 NA fiber

- Made in USA

Applications

- Space communications

- Power over fiber

- RF over fiber

Product Specifications

| Electro-optical | Symbol | Unit | Min. | Typical | Max. |

| Operating wavelength | λc | nm | 935 | 940 | 945 |

| Output power, CW | Po | W | 10 | ||

| Operating current | Io | A | 11.5 | 12.5 | |

| Threshold current | Ith | A | 0.6 | 1.9 | |

| Operating voltage | Vo | V | 1.75 | ||

| Power in 0.15NA* | % | 85 | |||

| Power conversion efficiency | PCE | % | 50 | ||

| Mean Tim to Failure (MTTF) | Hrs | 30,000 |

All values at P0=10 W, T=25°C

*0.22NA version

| Mechanical | Symbol | Unit | Min. | Typical | Max. |

| Case operating temperature (at P0) | Tc/sub> | °C | 0 | 50 | |

| Storage temperature | RH | °C | -40 | 85 | |

| Storage relative humidity | % | 5 | 95 | ||

| Fiber core diameter | m | 105 | |||

| Fiber NA | NA | 0.22/0.15 |

Request Information

"*" indicates required fields